We provide expert sheet metal Product Design from conception to completion.

Product design is the process of imagining, creating and iterating products that combine users’ needs with business goals in a given market to help consistently make successful products.

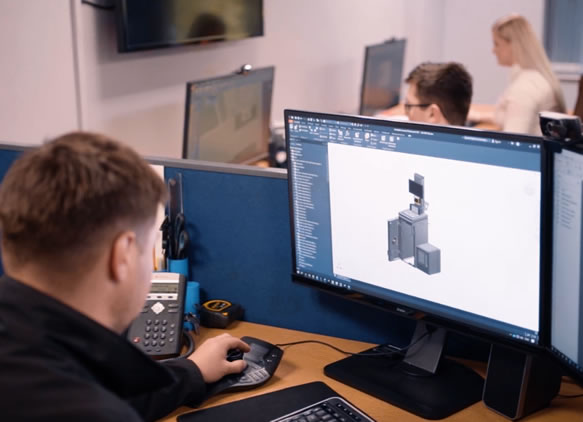

We utilise the latest technology in CAD software and the latest rendering techniques to provide life-like visuals and technical specifications. Our design team works closely with customers from conception to after sales to ensure that their needs are met.

Our service doesn’t just stop at design; we have a fast-track prototyping service where sketches are turned into working models within a matter of days. If we can improve it, we will.

If you would like to know more about our Product Design processes, feel free to Contact Us.

3D CAD

3D CAD (Computer Aided Design), is the use of computer software to assist in the creation, manipulation, analysis or optimisation of a design.

3D CAD modelling creates a virtual reality object that can have all the same properties as an actual physical object. Autodesk Inventor provides professional-grade 3D mechanical design, documentation and product simulation tools, allowing the team to work effectively and efficiently to create high quality designs.

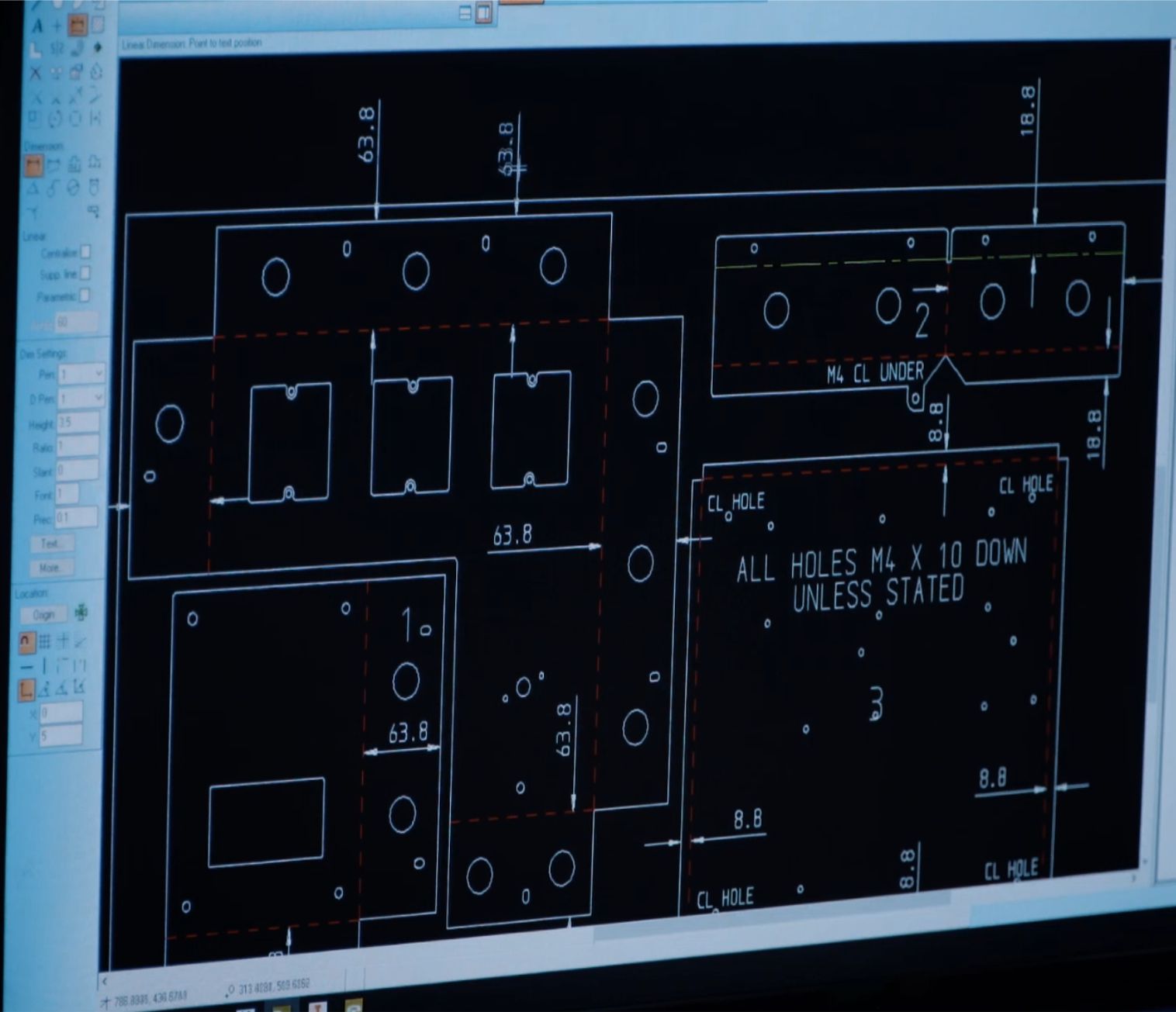

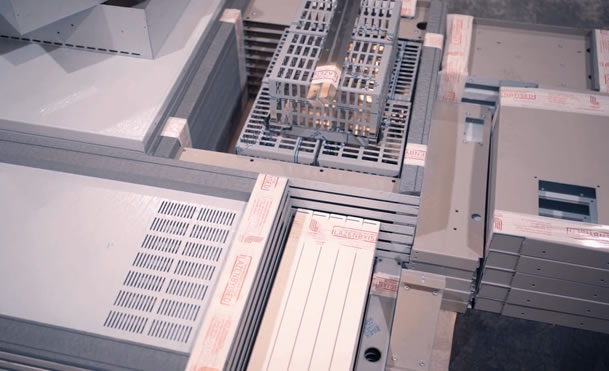

2D Tooling

2D Tooling is the use of 2D CAD CAM (Computer Aided Design and Computer Aided Manufacturing) software to make programming 2D parts easier than ever before.

The software RADAN is used, this is one of the world’s leading PC based CAD CAM software solutions for the sheet metal industry. It offers a unique combination of applications for punching, profiling, bending, design and production. 2D tooling is used to transform 3D parts into 2D ready to be manufactured on the workshop floor.

Prototype

A Prototype is an early sample, model or release of a product built to test a concept or process.

With prototypes, you can refine and validate designs, so the right product is then released. We have a fast-track prototyping service that can turn sketches into working models within a matter of days. Contact us for more information on prototyping.

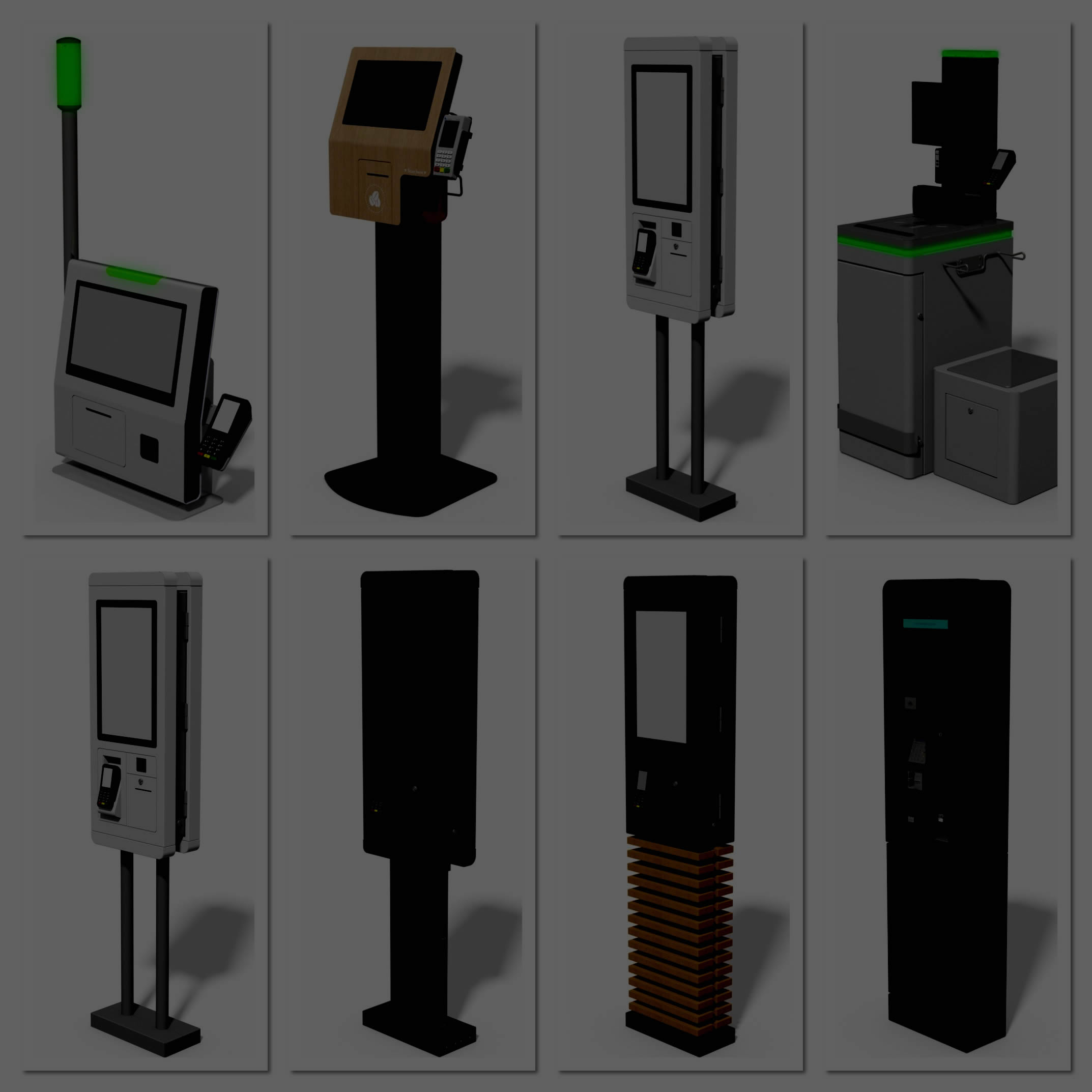

Rendering

Rendering is the process of generating a photorealistic image from a 2D or 3D model by means of a computer program.

We use the latest rendering techniques to provide life-like visuals and technical specifications.

Rendered images help explain or advertise concepts and designs, which we can work with customers to get the correct visual of how they want their product to look.

What our customers say

about our company

Frequently Asked Questions

Why choose The Lazenby Group?

The process can differ depending on what needs to be manufactured and what resources are already in place. In some cases, customers will already have a plan to submit to us; this is then drawn up with our software and sent through to the team to be manufactured. Along the way, if any adjustments need to be made, we will contact the customer and check that they are happy with any alterations before finalising anything.

The process can differ depending on what needs to be manufactured and what resources are already in place. In some cases, customers will already have a plan to submit to us; this is then drawn up with our software and sent through to the team to be manufactured. Along the way, if any adjustments need to be made, we will contact the customer and check that they are happy with any alterations before finalising anything.

In other cases, it will be a new design that we are working with. Here, customers will share their initial concepts and any mock-up drawings with us; from this point we can work with the customer’s ideas, offering advice on the best solutions along the way to create a finalised drawing.

Before completing a finalised CAD drawing, a rendered image can be produced, which is sent to the customer to give them a photorealistic concept. They can then check this and make any changes. The designer can then complete a final CAD image. We can also offer to produce a prototype.

Before any parts are manufactured, the design department create a CAD (computer aided design) model in 3D. The software that is used to do this is Autodesk Inventor, which can then be used to export and share the drawing with the team and with the customer.

Before any parts are manufactured, the design department create a CAD (computer aided design) model in 3D. The software that is used to do this is Autodesk Inventor, which can then be used to export and share the drawing with the team and with the customer.

The main file types we work with are DXF Files, DWG Files and STEP Files. However, our software, Autodesk Inventor, can work with virtually all CAD file types.

The main file types we work with are DXF Files, DWG Files and STEP Files. However, our software, Autodesk Inventor, can work with virtually all CAD file types.

The team of Product Designers here at Lazenby Group work with various materials and have substantial knowledge of the advantages, disadvantages and general properties of each one. The team can recommend materials, or on some occasions will suggest a material change to benefit you; this could either be a full material change, a thickness change, or possibly a different finish to the product.

The team of Product Designers here at Lazenby Group work with various materials and have substantial knowledge of the advantages, disadvantages and general properties of each one. The team can recommend materials, or on some occasions will suggest a material change to benefit you; this could either be a full material change, a thickness change, or possibly a different finish to the product.

Head over to our ‘Contact Us’ page, where you can attach a drawing to send to us and receive a quote. Fill in your details and we will be back in contact as soon as possible.

Head over to our ‘Contact Us’ page, where you can attach a drawing to send to us and receive a quote. Fill in your details and we will be back in contact as soon as possible.